OVERVIEW

Mechanism

BuMA™ is based on a unique design that possess technology advancements to solve the problem of 1st generation drug-eluting stents and enhances the safety benefits of bare metal stents. It is based on two different functional layers grown on the surface the metal (316L stainless steel) by chemical bonding: eG™ coating base layer (poly (n-butyl methacrylate coating) and biodegradable poly (lactide-co-glycolic acid) (PLGA) drug carrier in combination with Sirolimus.

ADVANTAGES IN SHORT

Mechanism

BuMA™ is based on a unique design that possess technology advancements to solve the problem of 1st generation drug-eluting stents and enhances the safety benefits of bare metal stents. It is based on two different functional layers grown on the surface the metal (316L stainless steel) by chemical bonding: eG™ coating base layer (poly (n-butyl methacrylate coating) and biodegradable poly (lactide-co-glycolic acid) (PLGA) drug carrier in combination with Sirolimus.

TECHNICAL INFORMATION

Mechanism

BuMA™ is based on a unique design that possess technology advancements to solve the problem of 1st generation drug-eluting stents and enhances the safety benefits of bare metal stents. It is based on two different functional layers grown on the surface the metal (316L stainless steel) by chemical bonding: eG™ coating base layer (poly (n-butyl methacrylate coating) and biodegradable poly (lactide-co-glycolic acid) (PLGA) drug carrier in combination with Sirolimus.

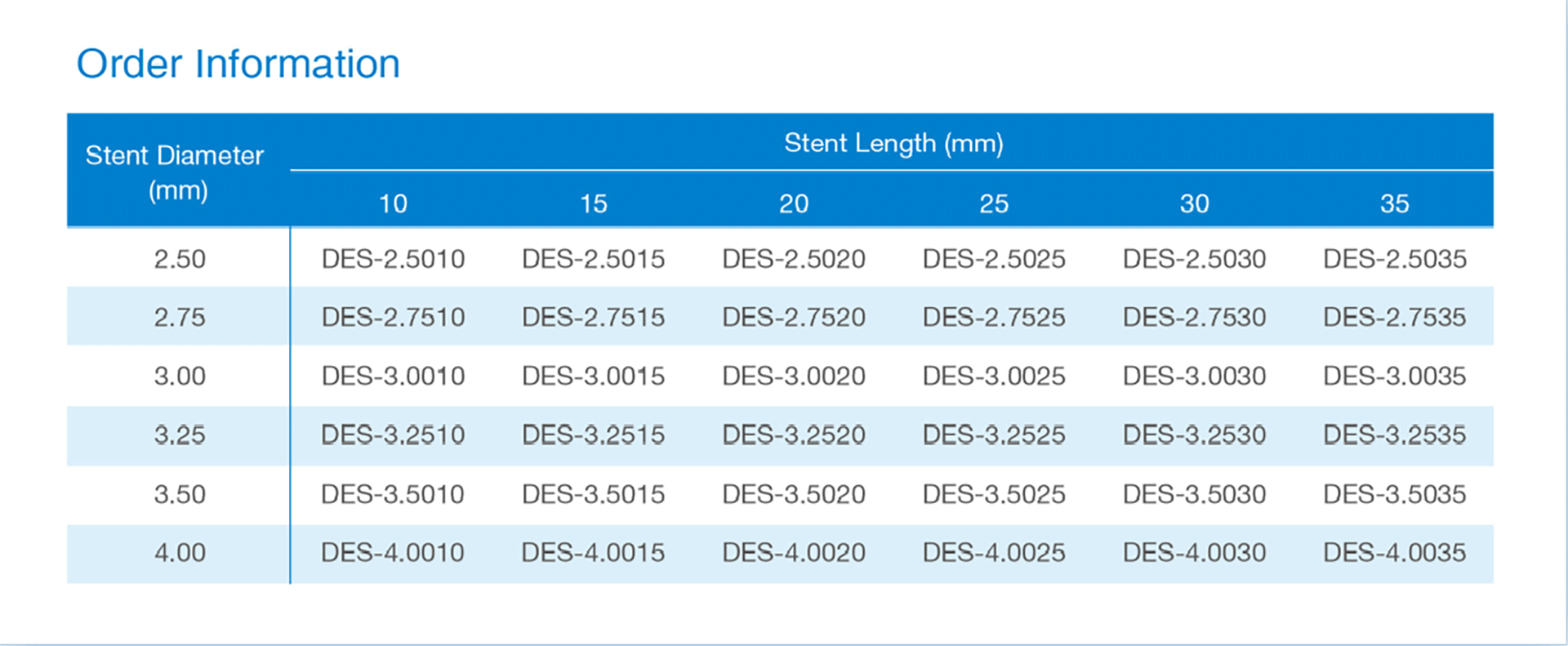

ORDER INFORMATION

Mechanism

BuMA™ is based on a unique design that possess technology advancements to solve the problem of 1st generation drug-eluting stents and enhances the safety benefits of bare metal stents. It is based on two different functional layers grown on the surface the metal (316L stainless steel) by chemical bonding: eG™ coating base layer (poly (n-butyl methacrylate coating) and biodegradable poly (lactide-co-glycolic acid) (PLGA) drug carrier in combination with Sirolimus.

BuMA™ is based on a unique design that possess technology advancements to solve the problem of 1st generation drug-eluting stents and enhances the safety benefits of bare metal stents. It is based on two different functional layers grown on the surface the metal (316L stainless steel) by chemical bonding: eG™ coating base layer (poly (n-butyl methacrylate coating) and biodegradable poly (lactide-co-glycolic acid) (PLGA) drug carrier in combination with Sirolimus.

Electro-grafting, the ideal coating solution for optimal adhesion and long-term safety

Through global collaboration, SINOMED adopted electro-grafting technology for its application on BuMA™ from a French company named AlchiMedics. Electro-grafting coating technology is a process of creating nanometric Velcro polymer layer to a metallic surface. It is a covalent bonding with a thickness of 100 to 200nm to the surface of the metal which generates polymer chains for optimal adhesion of biodegradable polymer and excellent uniformity on the complex stent surface. The base layer secures adhesion of the biodegradable PLGA matrix, and prevents from cracking and delamination upon expansion as result of interdigitation between the surface-anchored base layer polymer chains and the top PLGA matrix. The base layer also has the benefit of suppressing corrosion and ion release from metal stent substrates which could contribute to a lower local inflammation response in vivo.

ADVANTAGES IN SHORT

Strong adhesion function by eG™ coating system reduces cracking and delamination during expansion and over time.

Nanometric uniform layer of 100nm to 200nm promotes endothelial healing and inhibits inflammation from heavy metal release.

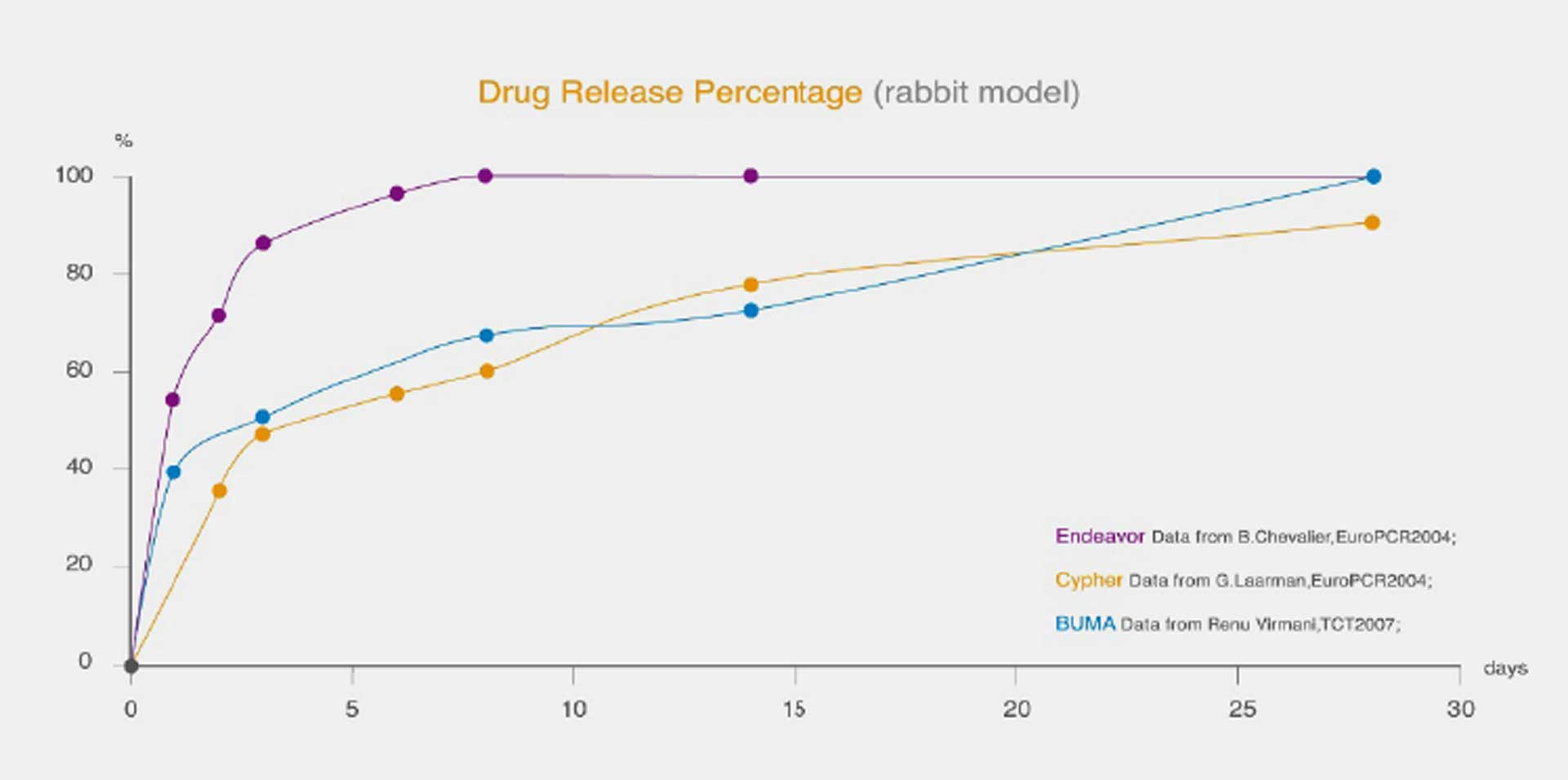

30 days complete drug release promotes early endothelial healing.

ORDER INFORMATION

BuMA™ is available in a unique 3.25mm size for accurate sizing that optimizes normal and acute performances.